What makes our service really unique?

Good service is one of our core values. At Mabo E&A we believe that internal transport is the blood vessel of a company. These have to keep circulating at all times or the company will grind to a halt. It is therefore crucial to ensure that our AGVs always run at peak performance without breakdowns. We do this by offering regular service.

Mabo E&A grew out of the Mabo Group, which has been providing excellent service for 36 years. AGV systems last a long time, also thanks to proper maintenance of the vehicles. This allows you to get the most out of your investment.

Mabo Service – On-time & Personal

Good service is one of our core values. At Mabo E&A we believe that internal transport is the blood vessel of a company. These have to keep circulating at all times or the company will grind to a halt. It is, therefore, crucial to ensure that our AGVs always run at peak performance without breakdowns. We do this by offering regular service.

Mabo E&A grew out of the Mabo Group, which has been providing excellent service for 36 years. AGV systems last a long time, also thanks to the proper maintenance of the vehicles. This allows you to get the most out of your investment.

- A complete service fleet

Mabo has 15 completely equipped service vehicles to be able to do repairs and maintenance on-site. - Several service centers

We have mutliple service centers: Lier, Vianen, Enkhuizen, Zulte, Izegem and Luxemburg! - Specialized technicians

Our technicians are experts in their field and regularly receive further training.

Mabo Service Agreements

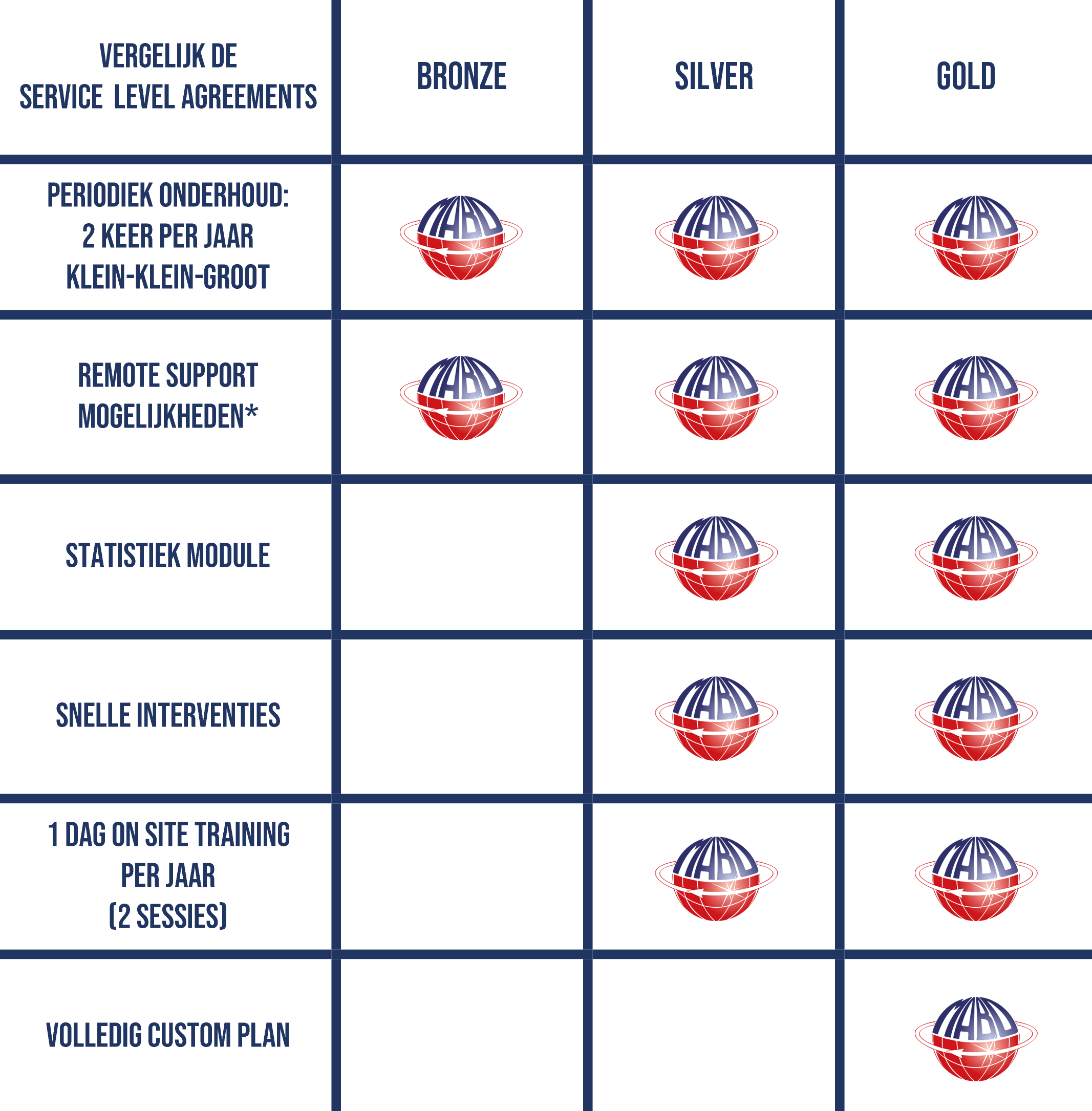

The Mabo Service Agreements are designed to offer the right package for you. We distinguish three levels: Bronze, Silver & Gold. Based on an audit of the project, Mabo E&A will advise on which service level is right for you.

*Remote access should be possible, 24/7 is optional.

Maintenance extends the lifespan of your machine

When you have your appliance serviced at regular intervals, you are actively extending its service life. Performing maintenance is therefore not only a smart move, it also saves money!

- Less wear

Regularly replacing oils and fats is crucial. Moving parts wear 6 times faster if this does not happen.

- Safer

Our engineers analyze the machine for any hidden defects during maintenance. This will alert you in advance, avoiding accidents at work.

- Enhanced driving experience

A well-maintained AGV operates smoother, consumes less and is more comfortable to work with.

Our experience has shown that the many consumable parts on an AGV have an average service life. If these parts continue to be used after wear and tear, they will have a detrimental effect on the performance of the AGV.

To prevent this, we draw up a maintenance schedule for each type of machine.